Components Inspection

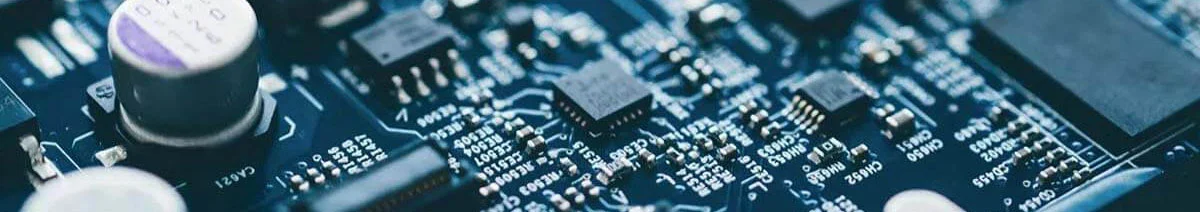

At Nuodichip, we understand the importance of quality control in the electronic components industry. That’s why we have a rigorous inspection process in place to ensure that every electronic component we sell meets the highest standards of quality and performance.

Our inspection process begins with a thorough review of the manufacturer’s specifications and datasheets. We then use state-of-the-art testing equipment to verify that each component meets the specifications and performance criteria outlined by the manufacturer.

Our team of experienced technicians performs a visual inspection of each component to check for any physical defects, such as cracks, chips, or other signs of damage. We also test each component for functionality, including power consumption, signal integrity, and other key performance indicators.

If any issues are discovered during the inspection process, we reject the component and it is not sold to our customers. We also keep a detailed record of every inspection, so we can easily track and monitor the quality of the components we sell.

In addition to our internal inspection process, we also partner with independent testing labs to perform additional tests and certifications as needed. This ensures that every electronic component we sell meets the highest industry standards and that our customers can trust the quality of the products they receive.

At Nuodichip, we’re committed to providing our customers with the highest quality electronic components available. Our rigorous inspection process ensures that every component we sell meets the standards of quality and performance that our customers expect and deserve.